![]()

Contents

Overview

. 3

Operation

4

Introduction

to Features

... 6

Introduction

to Internet Enabled

. 7

Features

Switching

Views

8

Work Centre

Collapse/Show

... 10

Change background

colours

... 11

Change work

order colours

. 13

Detailed

Tool tips

...... 15

Drag and

Drop

... 17

Internet

Enabled

19

Glossary

. 21

![]()

This user manual is to

guide the user through the visual production scheduling system (VPSS). The

intended users of this manual are users of Walstan Systems Beacon for Business

software package. This manual has been

created in conjunction with the

October 2004

Visual Production

Scheduling System (VPSS) User Manual

Overview

Welcome

to the VPSS user manual. The VPSS

application has been created to reduce the time it takes to manage the

production schedule. For this reason the

application consists of features and operations that are vital for quick and

efficient production scheduling.

The

VPSS user manual consists of a list of features and step by step instructions

on how to use these features to improve the process of production scheduling

for the user. The instructions have been

written in a simple format to make it easy for the user to understand and

follow.

A

Glossary has been included to provide the user with a list of words that have

been included within this manual and directly relate to production scheduling.

Operation Overview

The

VPSS application can be invoked through Beacon using two commands.

The

first is CRP.VP which displays Look only production schedule, which cannot be

modified

The

second command is CRP.VPC, which displays the production schedule and allows

changes to be made, through the drag drop mechanism.

There

are three separate views of the production schedule

The

first being the summary view, which only shows the summary of the capacity of

each work centre

The

Second view is the horizon view, which displays all the buckets that have been

specified on the capacity planning horizon e.g. days, weeks and months

The

third view is day details, which only displays the day buckets specified on the

capacity planning horizon.

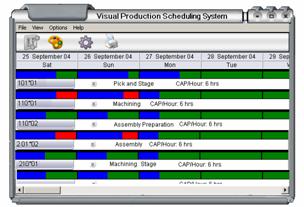

Figure 1: Day details View

Figure 2: Summary View showing capacity only

Features

As

already mentioned, the VPSS application has been created to make the task of

production scheduling a simple process.

The features that have been included in the application all contribute

to the goal of keeping it simple and easy to understand, therefore step by step

instructions have been included alongside the descriptions of these features

Here

is the list of the features:

ุ

Drag and Drop work

orders

ุ

Change

background colour

ุ

Change work

order colour

ุ

Work centre

expand/hide

ุ

Re-size date

column and Work centre row

ุ

Switching

between views

ุ

Detailed tool

tips

Internet enabled

As

already mentioned the aim of the VPSS application is to make production

schedule simple, which is why VPSS has the ability to work over the

internet. This means users can have

access to and make changes to the production schedule from remote locations.

The user does not need to have the Beacon server or the Beacon client pre-installed

on the computer they are working on, but all they have to do is type in the URL

in the internet browser and the application is automatically be downloaded onto

the users computer.

The

VPSS application connects to the web server, which connects to the Beacon

system where the user is requested to login using their Beacon username and

password.

Switching Views

This feature allows the

user to switch between the two views of the production schedule. There

are two views which display the production schedule in different ways.

The first is the Day

Details View, which displays the production schedule in proportion to the

capacity on the work centre, on a particular day. The Shadowboard View

is also the default view of the application when it is first opened.

The second view is the

Horizon View which displays all the buckets specified on the capacity planning

horizon. The scale is the same for each period in the factory calendar.

To use this feature:

To

switch to Horizon

To

switch to Horizon

(i) Select view

from the menu bar

(ii) Select Horizon

View

ุ

Note: Alternatively press the horizon

View icon button ![]()

Switch

to Day Details

Switch

to Day Details

(i) Select View

from the menu bar

(ii)

Select Day Details

ุ

Note: Alternatively press the day details

icon button ![]()

Full

Screen mode

Full

Screen mode

(i) Select View

from the menu bar

(i)

Select Full screen

ุ

Note: Or the alternative is to press to F12

on the keyboard to switch to full screen view and F11 to return to the

normal

view of the production schedule with the border around it.

Work Centre

Collapse

This feature allows the

user to hide/show the view of each work centre. This feature is used in situations

where the user does not need to view the details of each work centre.

The load indicator is still displayed, even when the work centre is hidden, allowing

the user to be aware of the load on each work centre on every day at all

times.

To use this feature:

(i) Click the hide/show button

which is located next to the work centre name.

If the

arrow is pointing up, the work centre collapses/hides from the view of the

user. If the arrow is pointing down, the work centre details

appear.

Figure 3: The location of the work centre

collapse button.

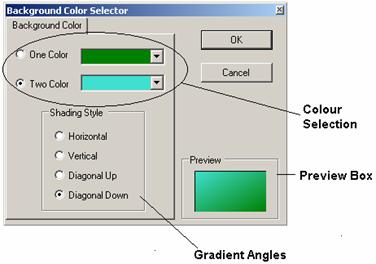

Change background

colour

This feature allows the

user to change the background colour of the application. There is a choice

of one or two colour shading and four gradient angles to select from to suit

individual preferences.

To use this feature:

(i) Select options from the tool bar and then

select customize.

(ii) Select background colour and the dialogue

box appears.

(iii) Select

either one or two colour background.

(iv) Select

angle

of the gradient from the

shading style box and preview the colour and the angle of the gradient

in the preview box.

(v)

Press ok.

ุ

Note: The colour of the background, now

displays the new colour and the angle of gradient selected. These colour settings are also saved, so they

appear with the same colours specified last time when the user view the

production schedule.

Figure

4: Change background colour dialog box.

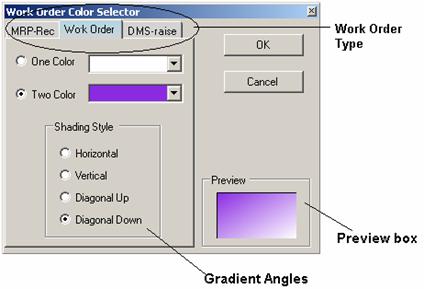

Change Work

Order colours

This feature allows the user

to change the colour of each type of work order displayed. Actual work orders

planned work orders and dynamically generated work orders may be shown in

different colours. The angle of the work orders can also be selected to suit

individual preferences.

To use this feature:

(i) Select options

from the tool bar and then select customize.

(ii) Select work order colour

and a dialogue box appears.

(iii) Select one of the

three tabs that relate to the three types of the work orders displayed.

(iv) Select either one or two colours

(v) Select the angle of the gradient

and preview the colour and the angle of the gradient in the preview box.

(vi) After all the selections have

been made, press ok.

ุ

Note: The colour of the work order, now

displays the colour and angle of the gradient that was selected. These colour

settings are also saved, so they appear with the same colours specified last

time when the user view the production schedule.

Figure 5: Work Order Colour dialog box

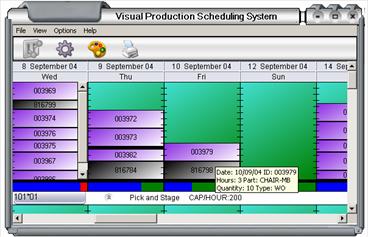

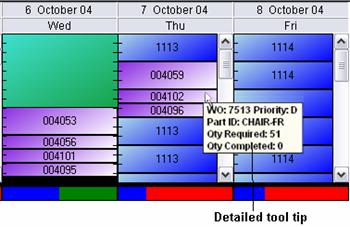

Detailed Tool

Tips

This feature of the VPSS

application allows the user to obtain detailed information about each work

order displayed, in a tool tip. The tool tip works by placing the mouse

cursor over the work order of interest and the tool tip will automatically

appear.

To use this feature:

(i) Place the mouse

cursor over the work order of interest.

(ii) The tool tip appears

while the mouse cursor is still over the work order.

ุ

Note: When

the mouse cursor is moved away from the work order, the tool tip disappears

Figure 6: Detailed Tool tip

Tool tip shows order type,

priority (if WO), part ID to make, description of part to make and quantity

required.

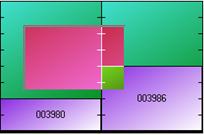

Drag and Drop

This feature of VPSS

application enables the user to select a work order and re-schedule it to

another day. This allows the

production schedule to be altered very easily without having to navigate through

the system. After the drag and drop procedure has been completed, the

database is updated with the altered information.

To use this feature:

(i) Select the work order to

be moved by clicking on it with the mouse.

(ii) While having pressing the

mouse, move the work order to its new location and release mouse.

(iv)

The work order

will now be associated with the new date and the work overload indicator is

updated to show the new capacity on that date period.

ุ

Note: The

Database is be updated with the change to the production schedule. Planned orders may not be changed, only WO

and DWO orders.

Figure 7: Example of a work order being moved

Internet Enabled

The VPSS application is web

enabled, which means the user can access the application from remote

locations and make changes to the production schedule while being away from the

factory.

First download the VPSS

application form the internet, log into the system using the Beacon login and then

view and make changes to the production schedule.

The user is prompted to

login at two places; first is when the user enters the URL in the internet

browser and the second is when the user tries to log into the Beacon

system.

To use this feature:

(i)

Open internet explorer

(ii) Type

in the URL in the address field

ุ

Note: A

dialogue box appears asking to save the Zip file on the users computer

(iii) Click Save and specify the

directory

where the file is to be stored.

(iv) Unzip the folder and 3 files file

will unzipped.

(v) Double click on the .exe

file and the user is prompted to log in using the Beacon login

ุ

Note: Once the

login is authenticated and the connection to the web server has been made, the

production schedule is displayed on the client computer.

Glossary

ERP

Machine Where goods are manufactured

Overload This is when the maximum capacity of the work

centre has been exceeded.

Planning Board

Used by production planners to create a physical representation of the load on

each work centre.

Production Planner

Plan timetables and resources allocated to work centres in order to ensure

smooth operation of factory, primary user of VPSS.

Shop Floor - This refers to the area that manufactures the

products that have been included in the Work Order

UniVerse Extended

relational database ideal for rapid, cost-effective vertical application

development (IBM)

VPSS Visual Production Scheduling System

Day Details View Production schedule displayed which only shows

days specified in the shop floor calendar.

Horizon View Production schedule displayed that shows days,

weeks and months depending on the number of buckets specified.

Bucket Represents a time bucket on the capacity planning

horizon e.g. days, weeks, months etc.

Work Centre

This is defined as consisting of one or more machines

Work Order A document which

authorizes the manufacturing of a particular item.

Planned Work Order Order raised by MRP, which will be required to

meet the MPS.

DWO Work Order Order generated by Beacons DMS (Dynamic

Manufacturing Scheduling) feature. This

order is required to meet current promises to customers.

MPS Master Production Schedule. The

plan of what the company intends to make over the planning horizon.

MRP Material Requirements Planning calculation of what material is

required to meet the MPS

Planning horizon Time for which a company plans its production,

consisting of planning buckets.

Smart Client Technology Combines the rich client based model with the

browser based client to provide an effective application that is functional

over the internet.